Our Technology

At LimaCorporate, we have a conviction to outdo ourselves and drive innovation. In everything we do, we challenge the status quo to progress digital and hardware technology. We look to continually transform orthopedics for patients.

Our technological solutions are developed by an enthusiastic team to empower surgeons, and to improve patient outcomes from joint replacement surgery. Research into new materials drives our offering of next-generation products. This puts us at the forefront of implant technology, designed for enhanced longevity and performance. Our game-changing approach has led to the development of multiple technologies that are internationally recognized in orthopedics.

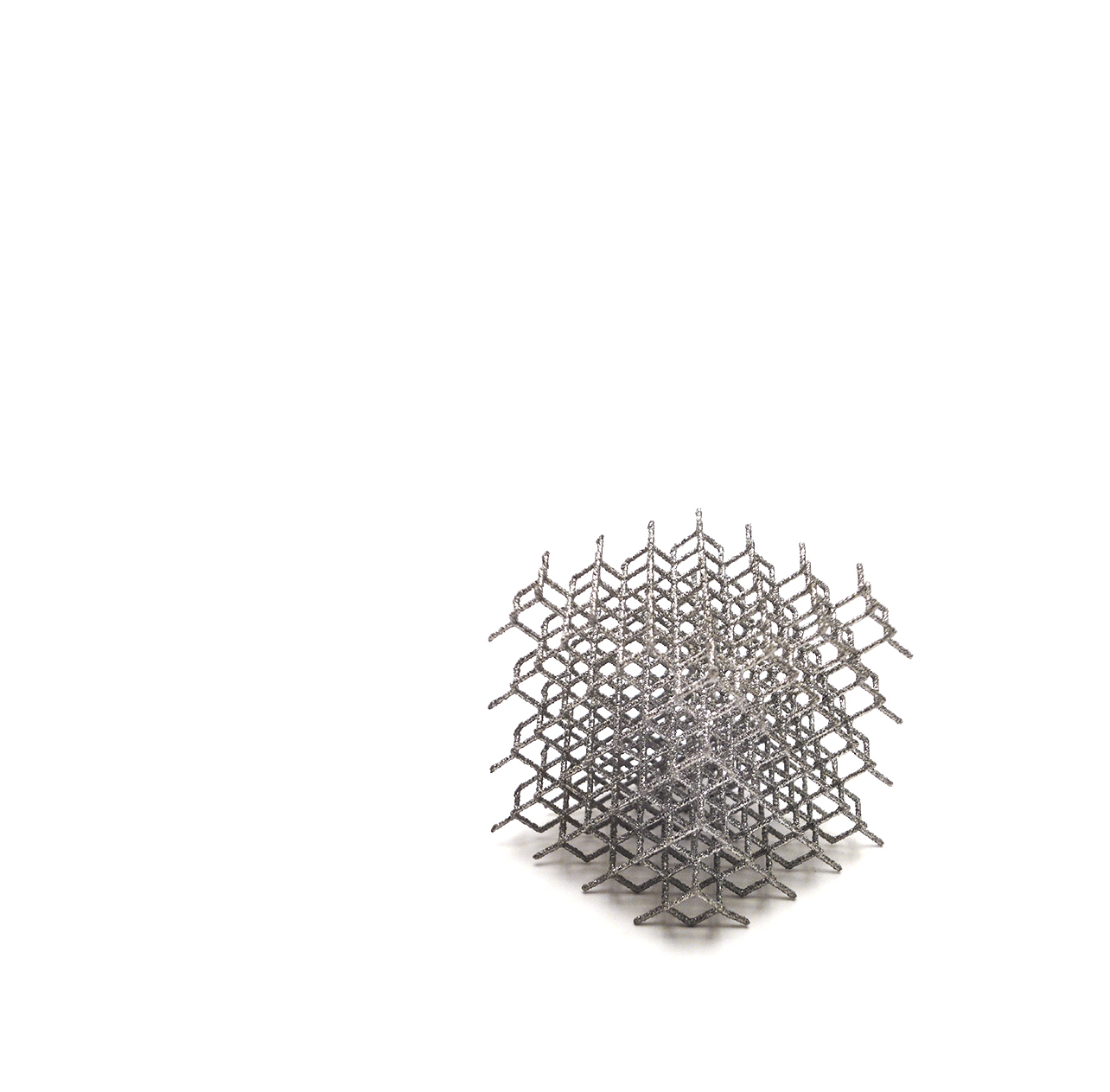

Trabecular Titanium

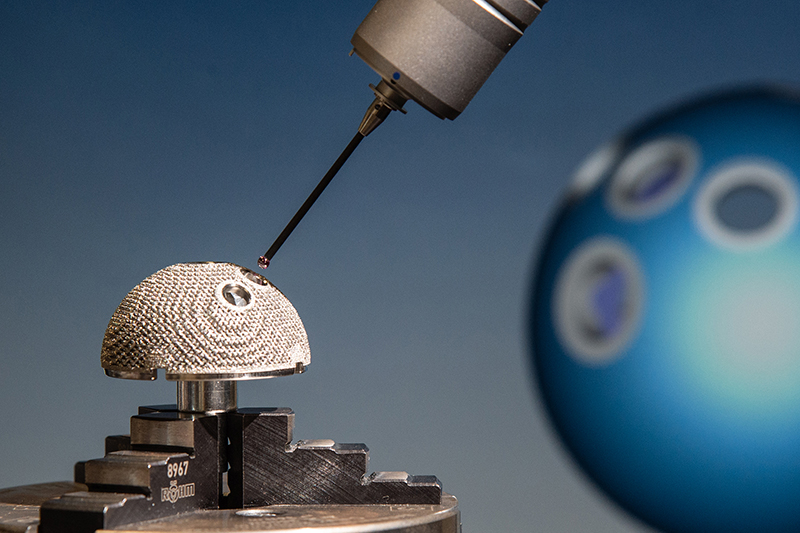

Trabecular Titanium is a biomaterial that forms a unique net geometric structure. It is an interconnected design that can only be constructed using 3D printing technology.

Trabecular Titanium

Trabecular Titanium is a biomaterial that forms a unique net geometric structure. It is an interconnected design that can only be constructed using 3D printing technology.

It is extensively used in reconstructive orthopedics as it is lightweight, has high biocompatibility and mechanical performance. The prosthetic components in Trabecular Titanium are built using Electron Beam Melting (EBM) technology. The technology uses a high-energy focused beam to melt metal powdered layers, forming Trabecular Titanium.

Advancing 3D Printing

LimaCorporate has pioneered 3D printing in orthopedics.

Our Research & Innovation Center is in LimaCorporate’s headquarters in San Daniele, Italy and covers an area of 1000 square meters.

A team of 50 engineers lead on research and product design, partnering with renowned orthopedic surgeons. Raw materials, combined with the latest digital technologies are transformed into 3D printed orthopedic implants. We also continually experiment with new and innovative materials, as we continually seek to improve the lives of patients around the world.

A team of 50 engineers lead on research and product design, partnering with renowned orthopedic surgeons. Raw materials, combined with the latest digital technologies are transformed into 3D printed orthopedic implants. We also continually experiment with new and innovative materials, as we continually seek to improve the lives of patients around the world.

Leveraging 3D Printing Technology in complex orthopedic cases

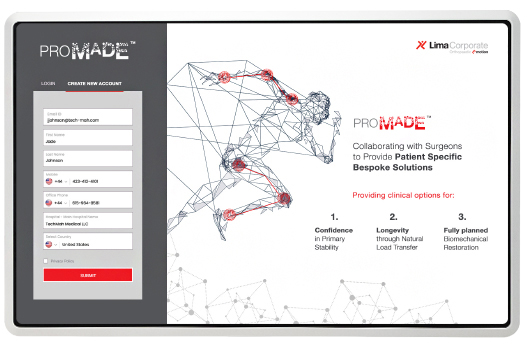

The ProMade Design service is focused on collaborating with surgeons to design and manufacture bespoke solutions for complex orthopedic cases.

LimaCorporate began leveraging the capabilities of 3D printing before Titanium EBM printers were commercially available. With 3D printing we create an advanced porous surface to increase the implant’s primary stability and enhance biologic integration. The ability to create anatomy matching geometries and engineer the modulus of elasticity allows for natural load transfer and increased longevity.

The clinical advantages of LimaCorporate’s 3D printing and ProMade’s clinical heritage have surgeons around the world selecting the ProMade Design Service to collaborate with on their most complex orthopedic cases.

Go to our ProMade Platform

The clinical advantages of LimaCorporate’s 3D printing and ProMade’s clinical heritage have surgeons around the world selecting the ProMade Design Service to collaborate with on their most complex orthopedic cases.

Go to our ProMade Platform

LimaCorporate and the Hospital for Special Surgery (HSS)

The ProMade PoC Center for Complex Orthopedic Solutions is the first Point of Care center for complex cases operated by a medical device company on hospital grounds.

LimaCorporate, a leader in the design and 3D printing of complex orthopedic solutions, partners with HSS, the top-ranked US orthopedic hospital 10 years running. This brings LimaCorporate’s advanced technology, design and 3D printing experience, and HSS’ clinical care and bio-mechanical engineering expertise to one location.

The new ProMade PoC Center houses LimaCorporate’s US ProMade Design Team and 3D manufacturing center. The daily collaboration between the HSS surgeons, the HSS engineers, and now the ProMade engineers with the resultant collaborative intelligence will advance clinical solutions to complex orthopedic cases around the world.

The new ProMade PoC Center houses LimaCorporate’s US ProMade Design Team and 3D manufacturing center. The daily collaboration between the HSS surgeons, the HSS engineers, and now the ProMade engineers with the resultant collaborative intelligence will advance clinical solutions to complex orthopedic cases around the world.