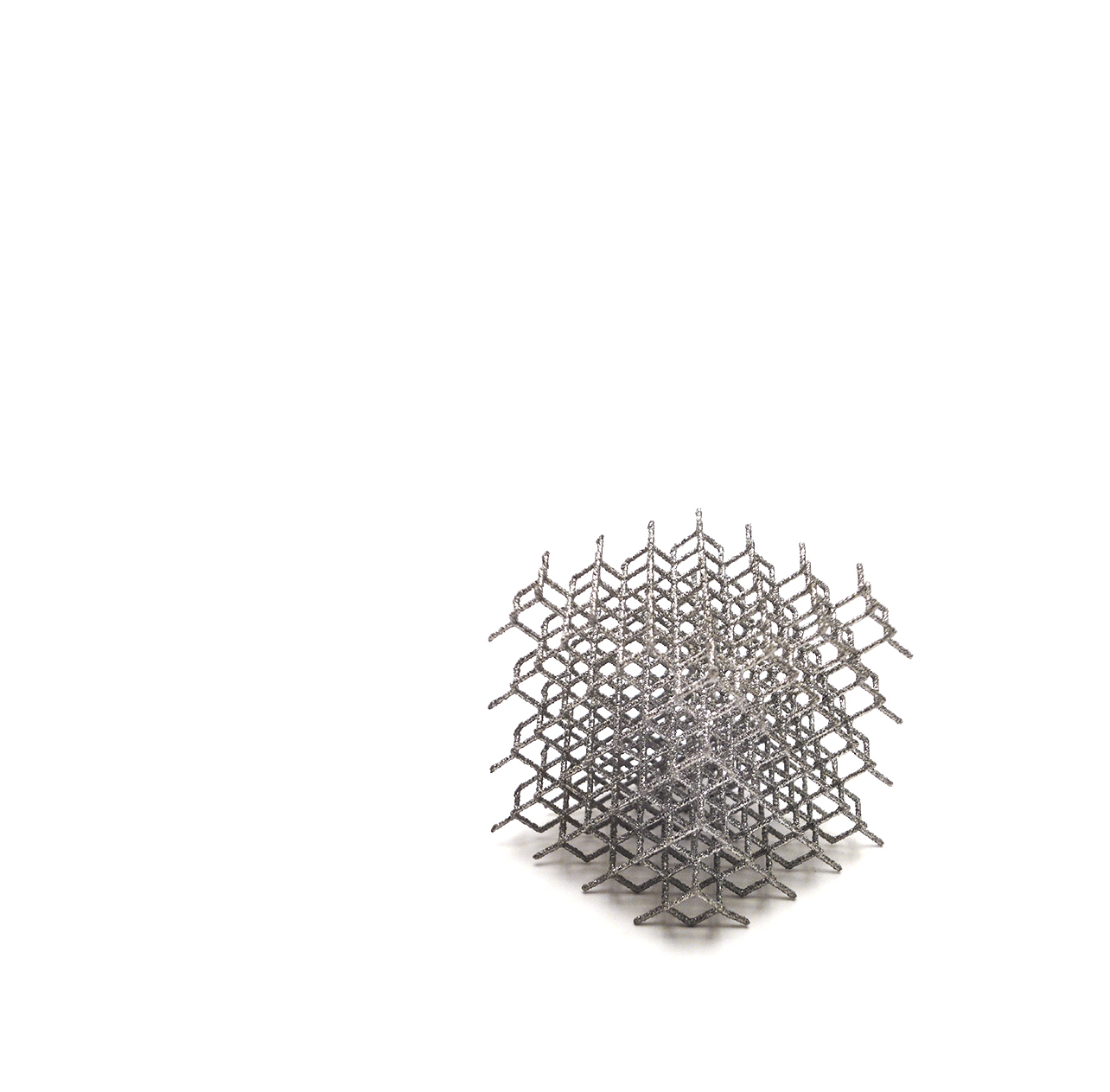

Trabecular Titanium & 3D Printing

Our Research & Innovation Center is in LimaCorporate’s headquarters in San Daniele, Italy and covers an area of 1000 square meters.

A team of 50 engineers lead on research and product design, partnering with renowned orthopedic surgeons. Raw materials, combined with the latest digital technologies are transformed into 3D printed orthopedic implants. We also continually experiment with new and innovative materials, as we continually seek to improve the lives of patients around the world.

3D Printing

TT is a biomaterial that forms a unique geometric structure. Its interconnected design can only be constructed using 3D printing technology.

Reconstructive Orthopedics

TT is used in reconstructive orthopedics as it is lightweight, corrosion resistant, has high biocompatibility and mechanical performance.

EBM

TT components are built using Electron Beam Melting (EBM) technology. A high-energy focused beam that melts metal powdered layers, forming Trabecular Titanium.